THERMAL CERAMICS IN ALUMINUM AND STEEL INDUSTRY

Advanced Monolithic Refractories for Lining Aluminum Melting & Holding Furnaces

History of Refractory Linings in Aluminum Melting Furnaces

- Melting & holding furnaces traditionally lined with brick.

- Tri-Mor monolithic refractories first used in roof and upper walls.

History of Tri-Mor Monolithic Linings in Aluminum Furnaces

Introduction of Low Cement Castables

- In 1980’s Tri-Mor Low Cement Castables first used in high wear areas such as ramps.

- Tri-Mor LCC’s have ultrahigh strengths and good abrasion resistance.

- Good performance in these areas increased their used to other areas of the furnace.

Alcast Extra Installed into hearth of 80T capacity holding furnace

Failure Mechanisms of Refractory Linings in Aluminum Furnaces

- Corundum growth

- Mechanical damage

- Metal penetration

- Thermal shock

- Erosion

- Chemical attack

Corundum Growth in Furnace Linings

- Hard, high temperature form of aluminum oxide

- 4Al(l)+ 3SiO2(s) 2Al2O3(s) + 3Si(l)

- Reduces furnace operating efficiency

- Eventually leads to premature failure of refractory lining

Factors Affecting Corundum Growth

- Temperature

- Alloy Composition

- Furnace Atmosphere

- Furnace Housekeeping

- Refractory Lining

Effect of Furnace Temperature on Corundum Growth

- Increasing furnace temperatures has a dramatic effect on formation of corundum

- Particularly with alloys high in Silicon

IRON & STEEL - REFRACTORIES FOR PRODUCTION & TREATMENT

Steel plant – scheme

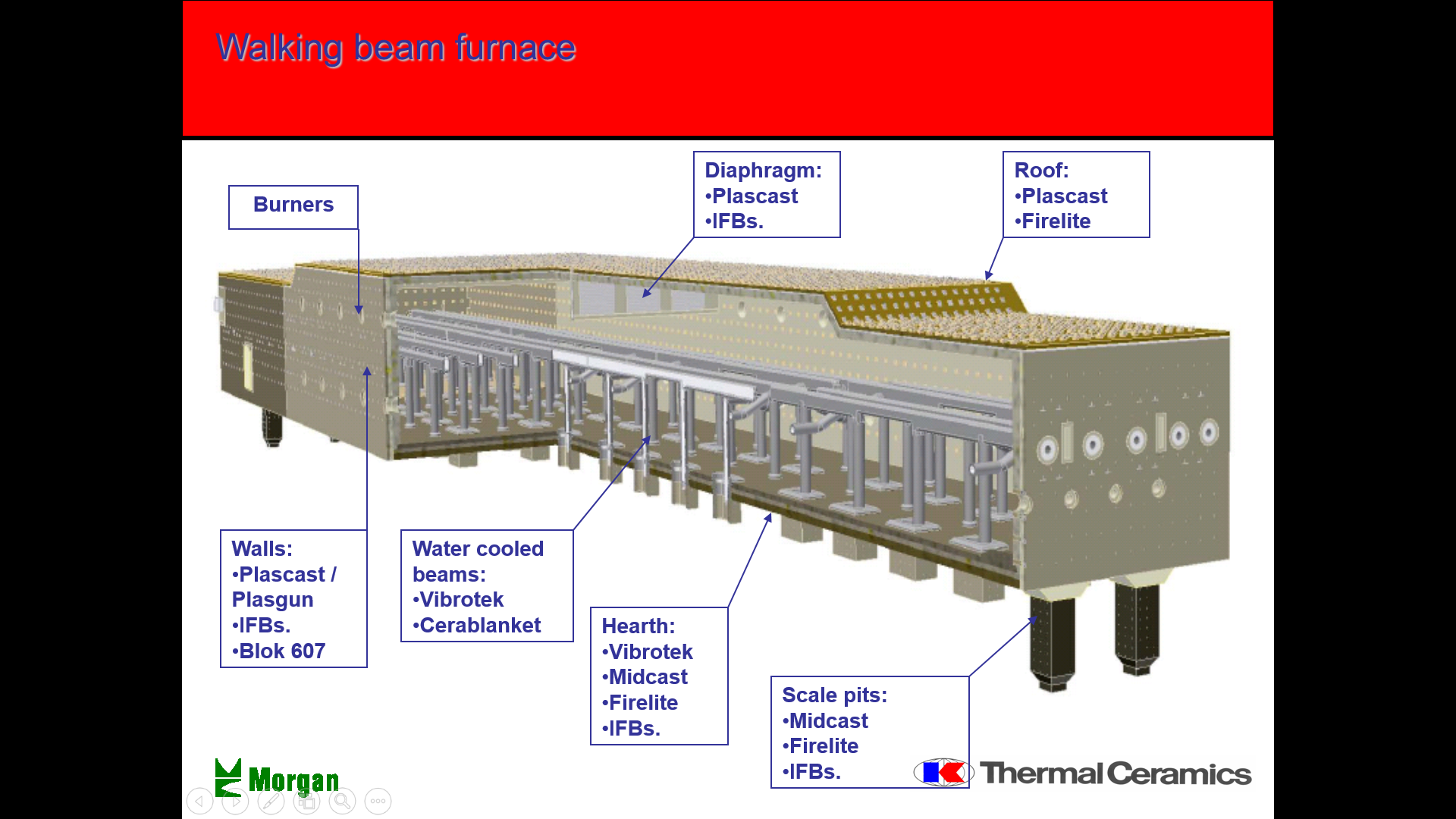

Walking Beam Furnace

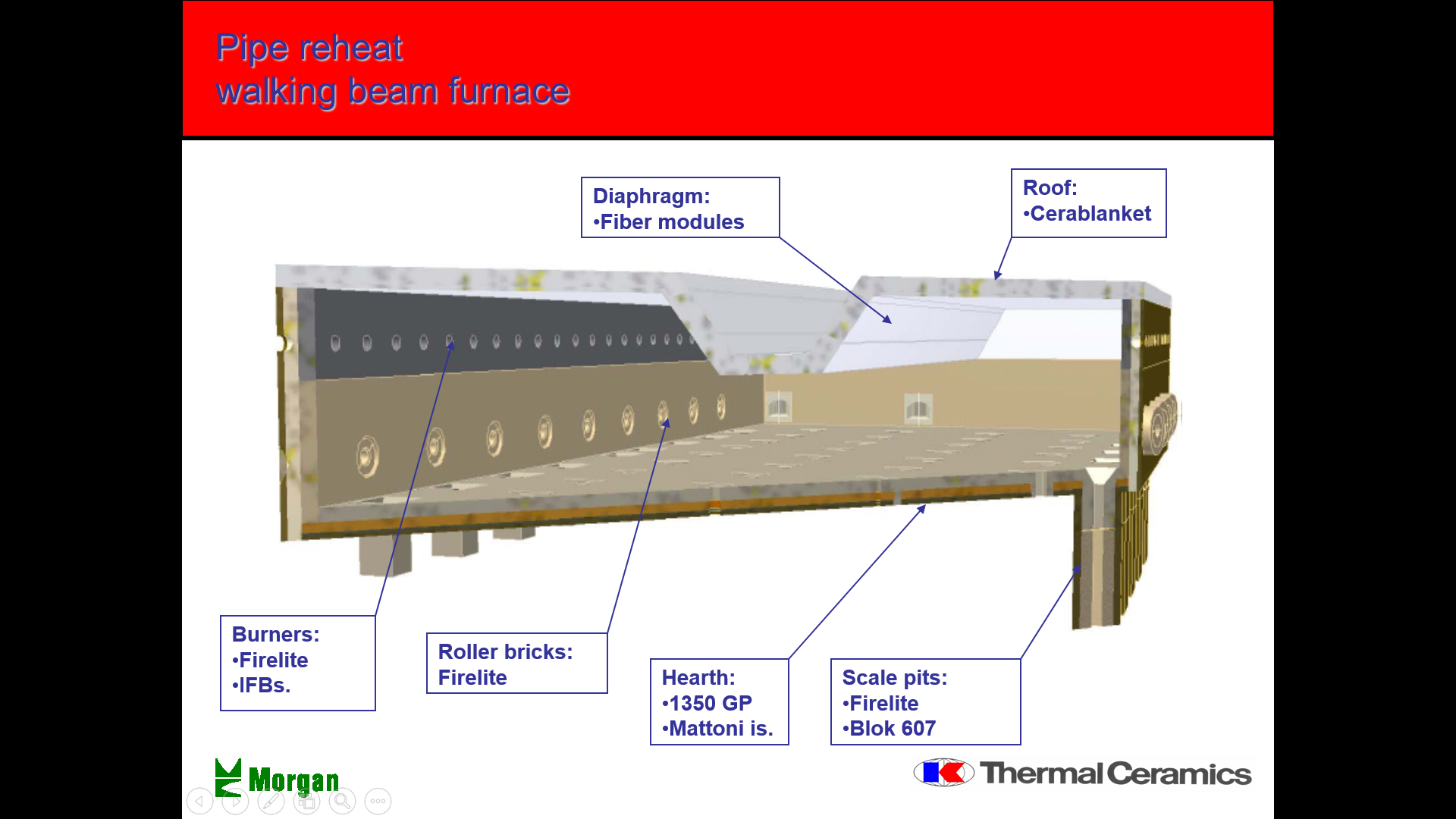

Pipe Reheat Walking Beam Furnace

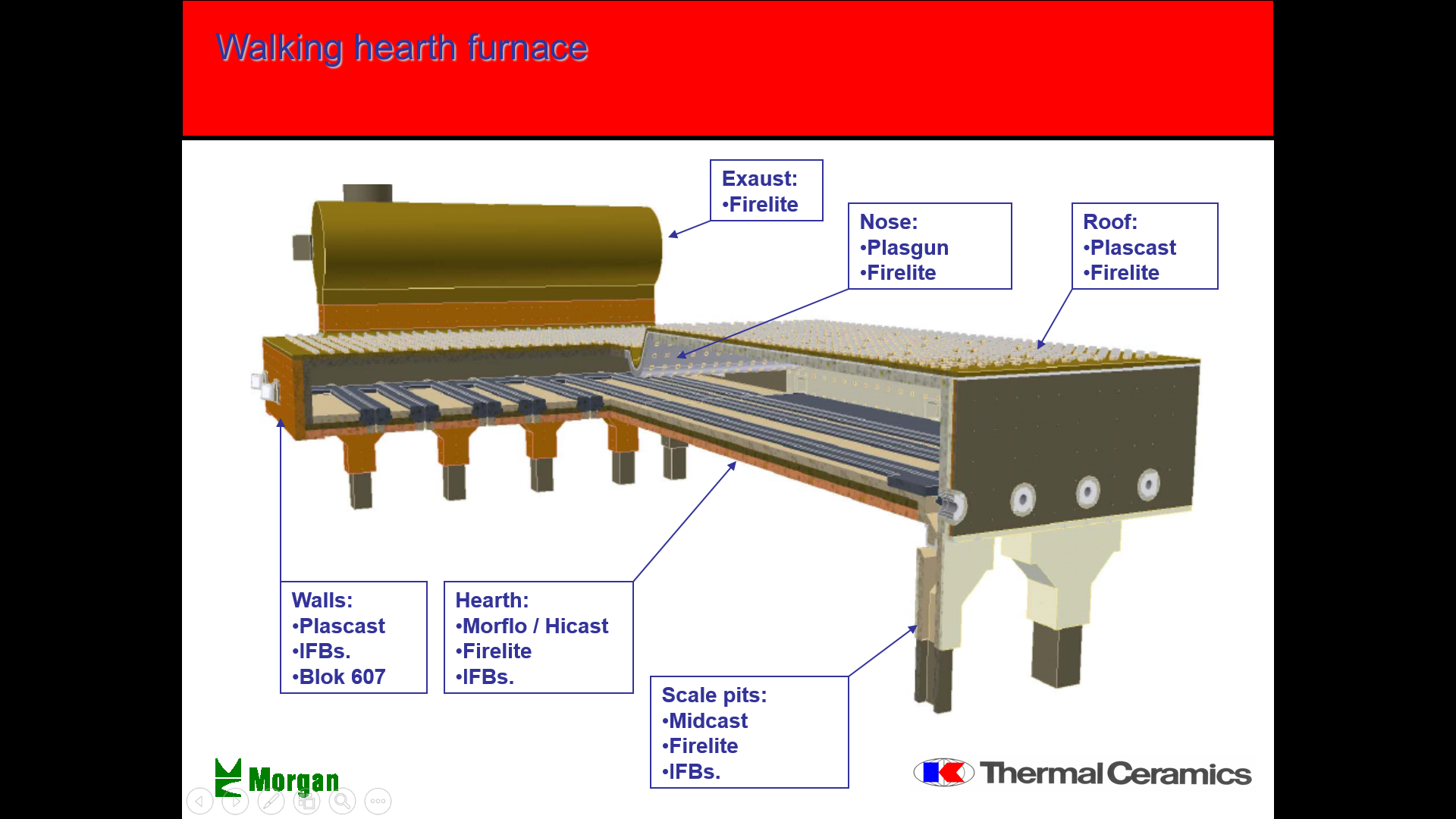

Walking Hearth Furnace

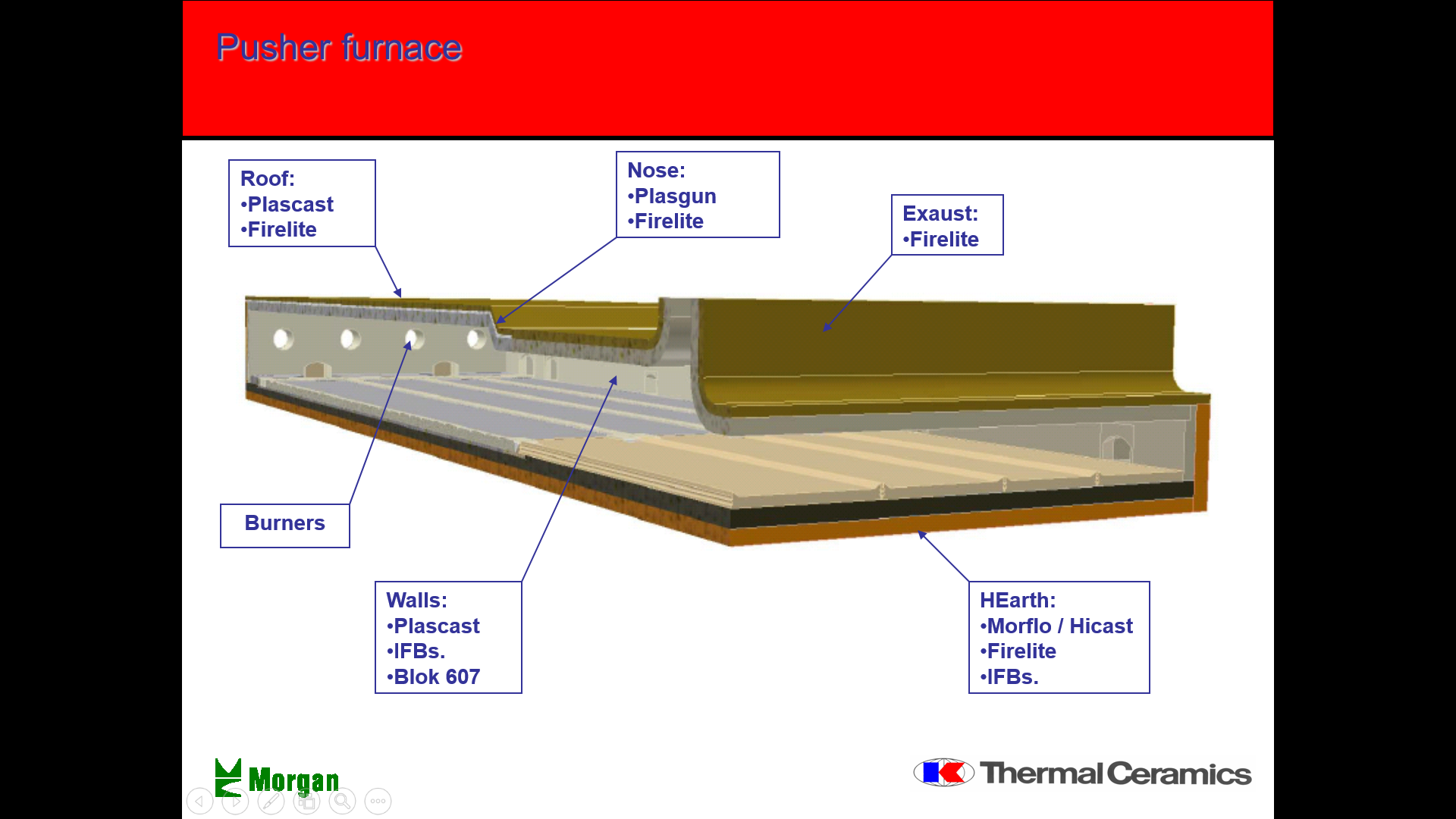

Pusher Furnace

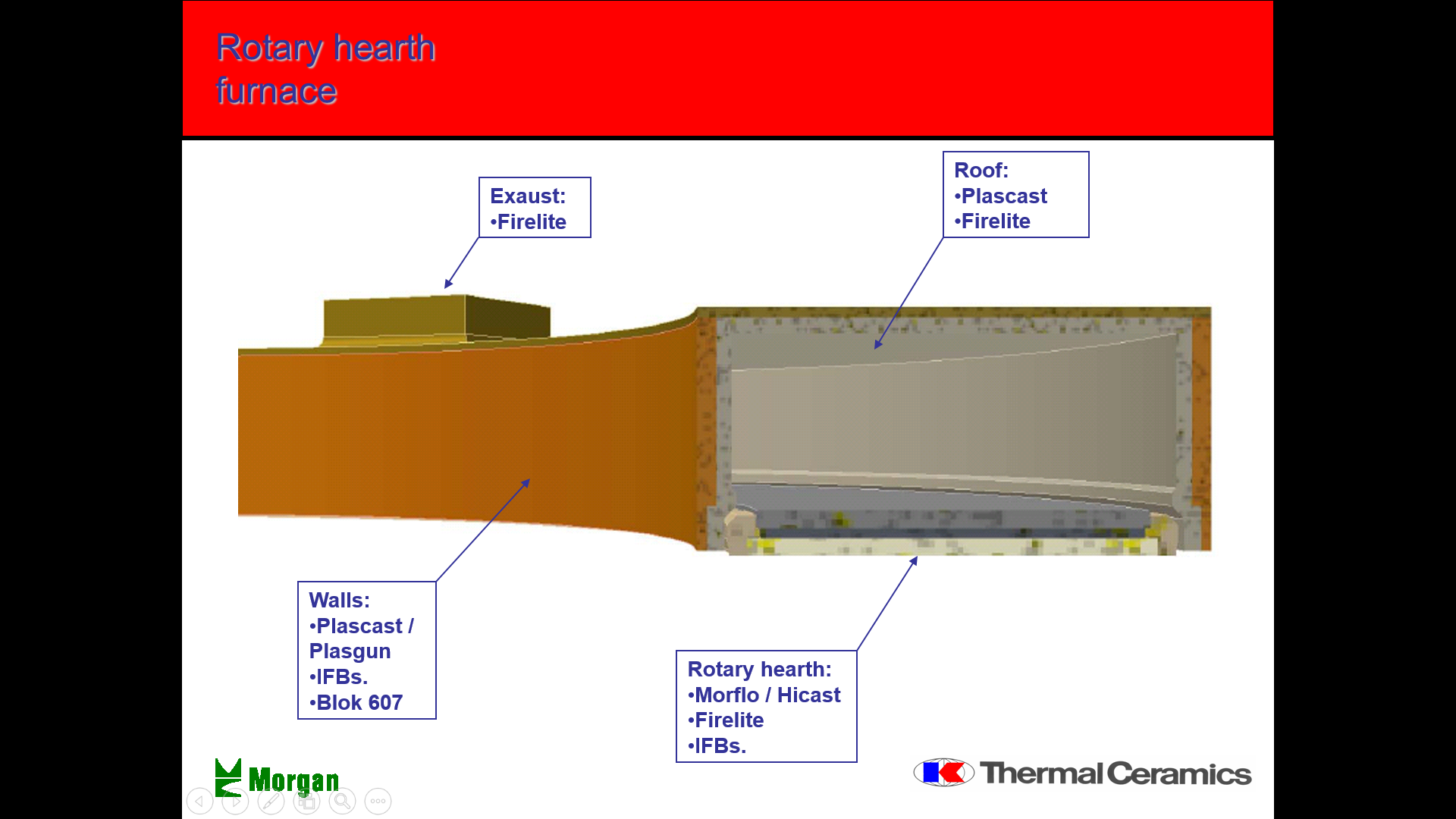

Rotary Hearth Furnace

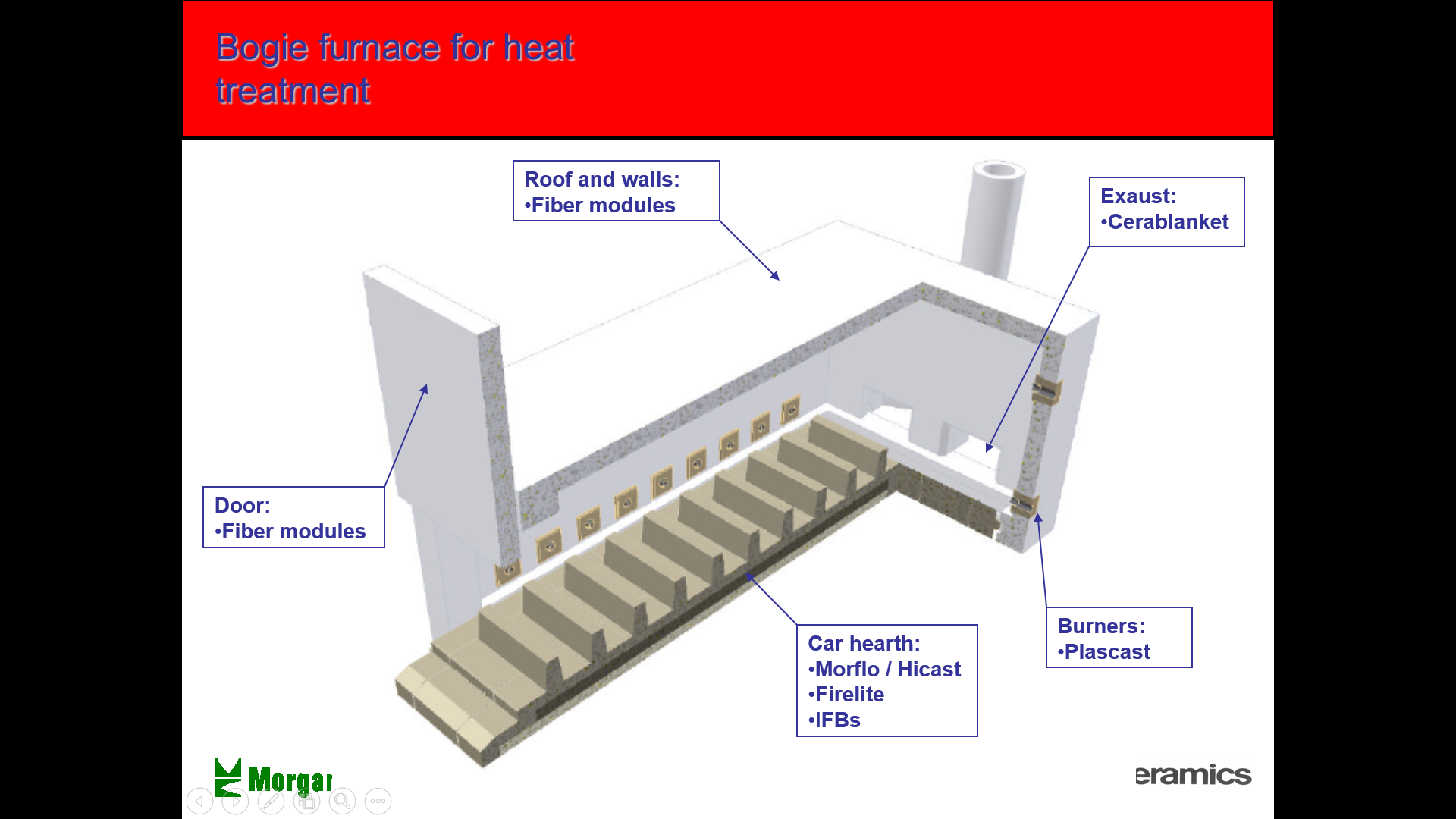

Bogie Furnace for Heat Treatment

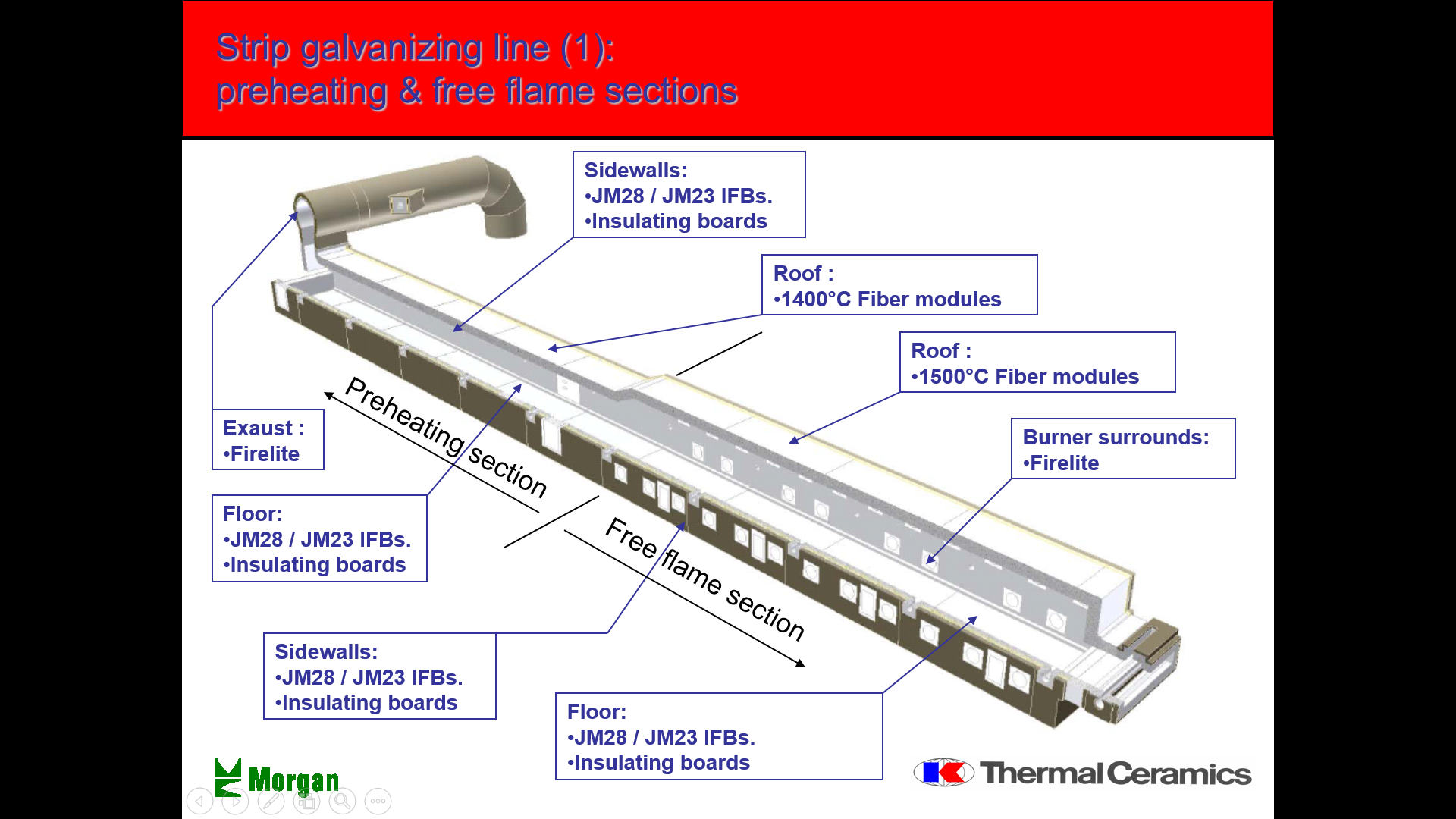

Strip Galvanizing Line (1): Preheating & Free flame Sections

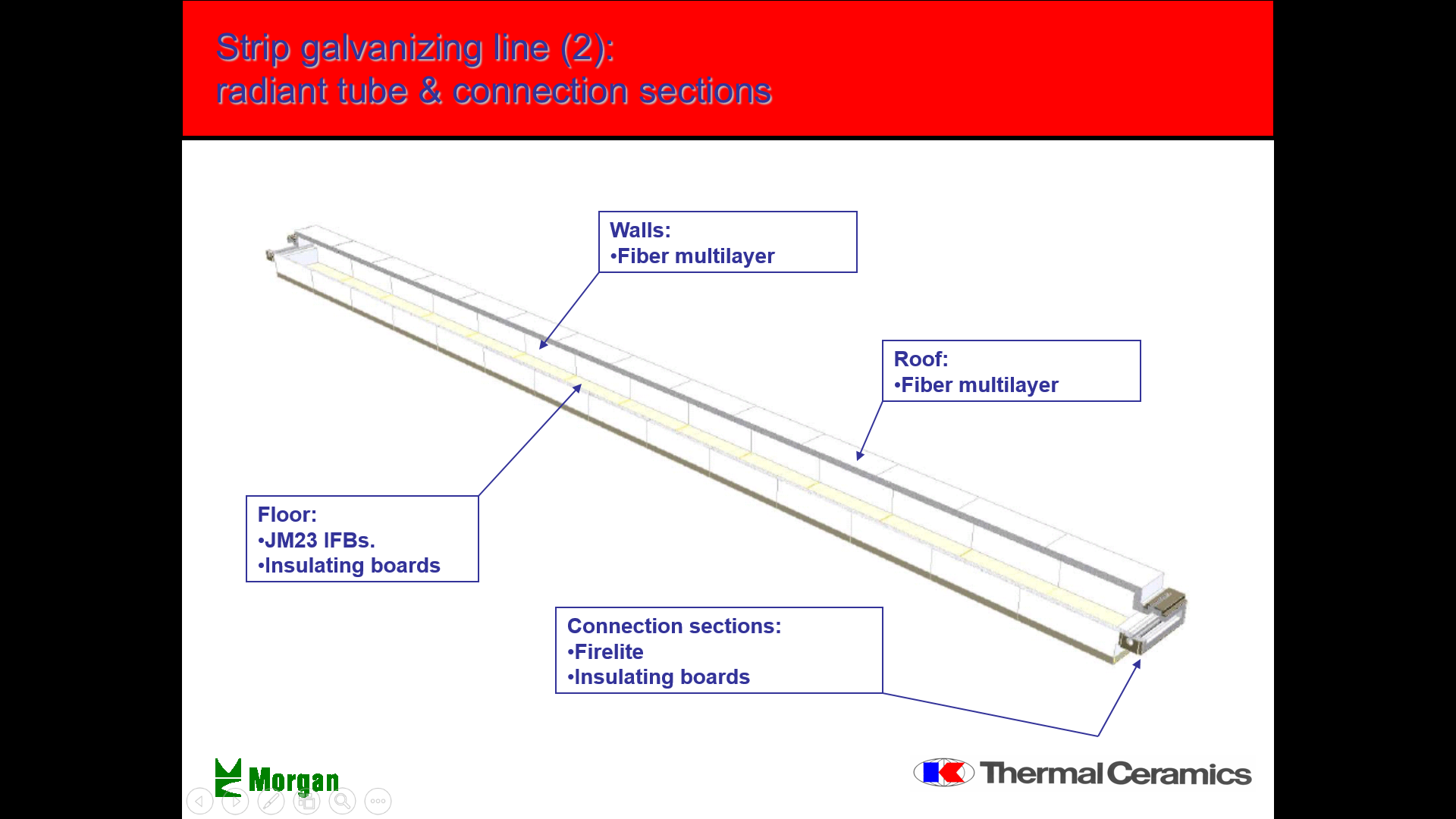

Strip Galvanizing Line (2): Radiant Tube & Connection Sections

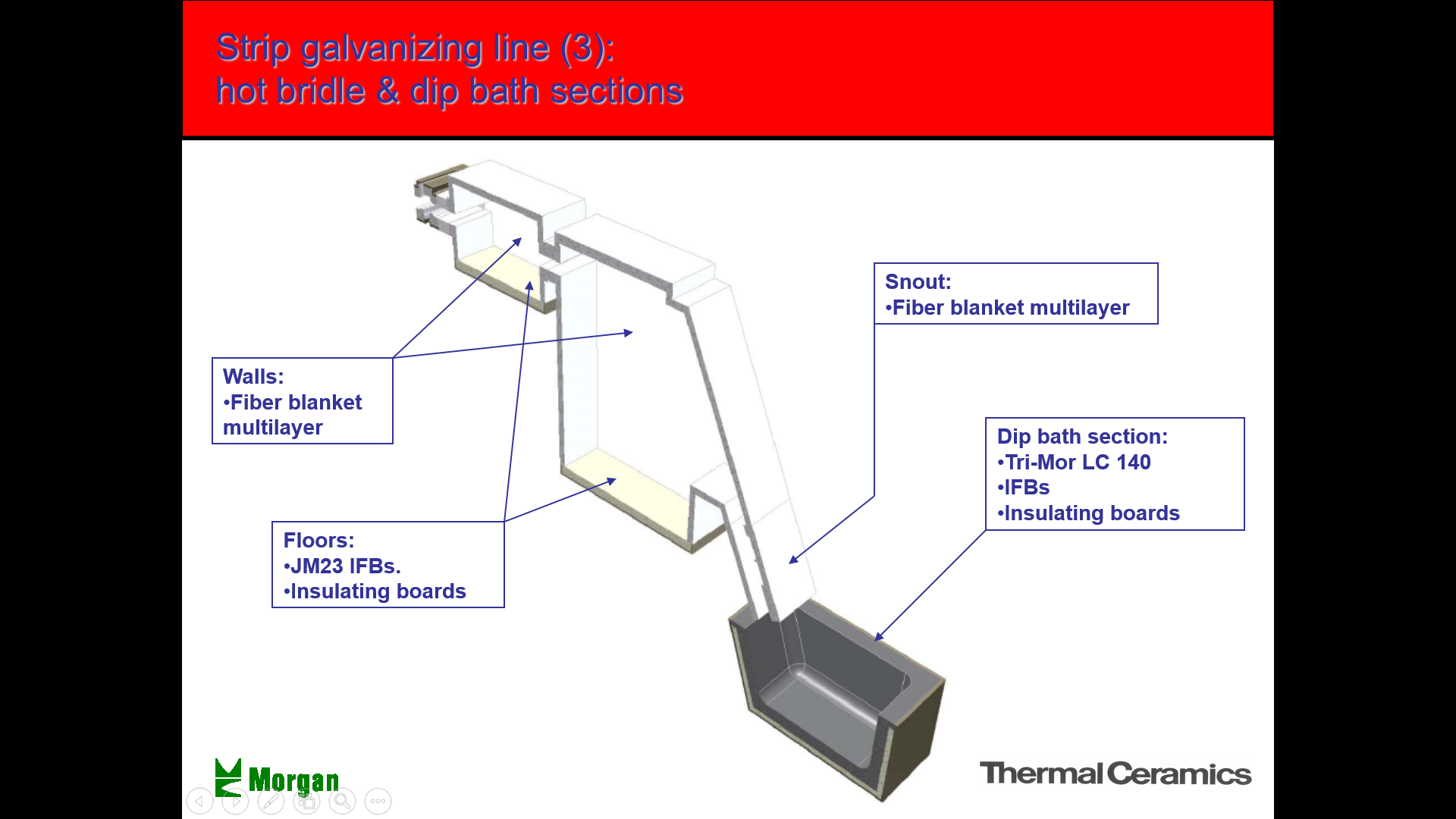

Strip Galvanizing Line (3): Hot Bridle & Dip Bath Sections

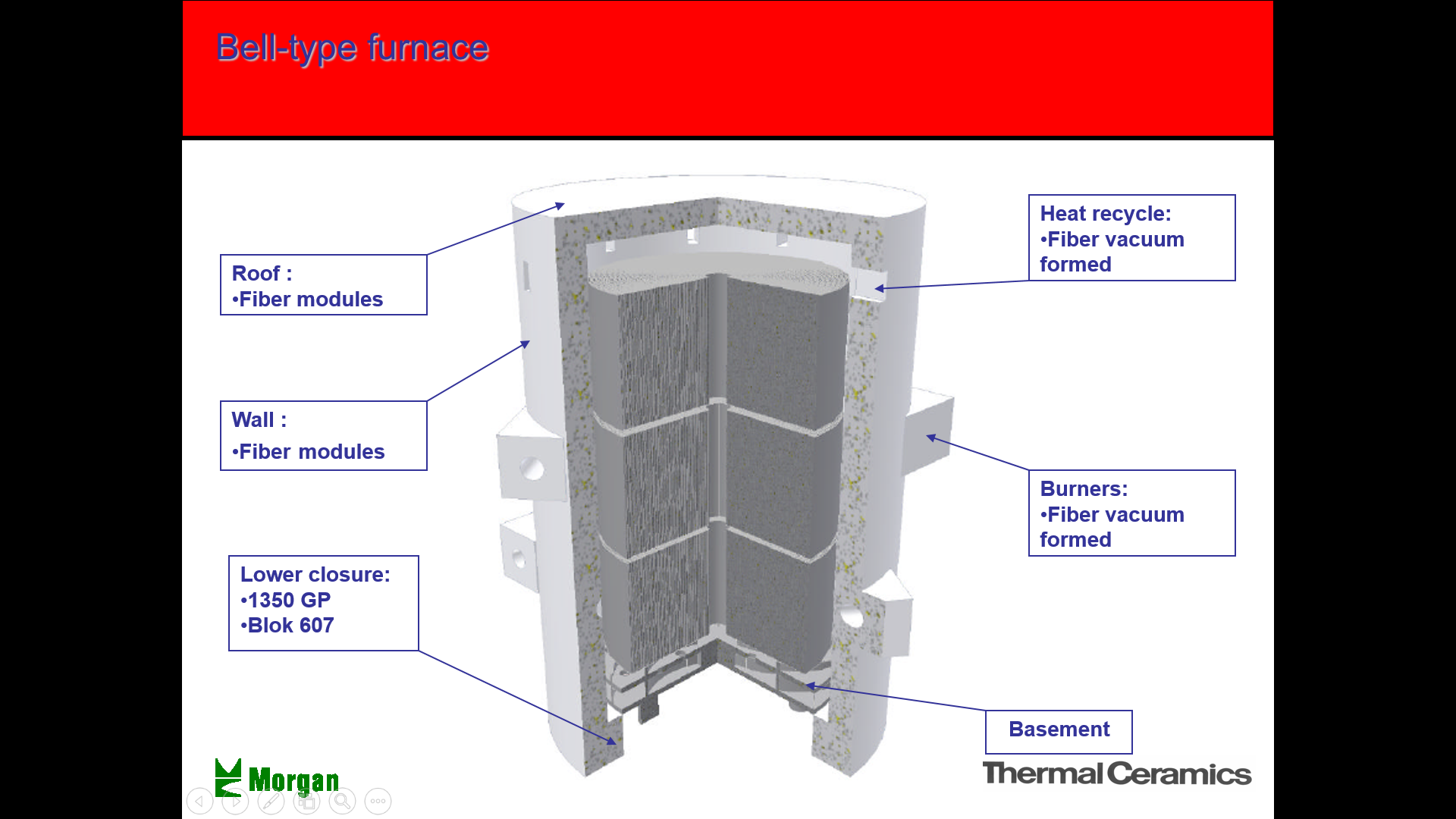

Bell-Type Furnace